Plan- Do- Check- Act - A Practical and a systematic approach for managing changes, bringing effectiveness and knowing the areas of improvement.

When the assessed risk is above the broadly acceptable level, but below the unacceptable level, then risk reduction is expected to be carried out by a corporation to a level ‘As Low As Reasonably Practicable’ (or ALARP).

As it is generally known that plant operation is undertaken with risks. Risk is the possibility that harm (illness, injury or death) might occur when plant personnel or equipment expose to a hazard. Theoretically, all foreseeable risks must be identified and managed through a structured process. Because risk cannot be completely eliminated, it is however possible to be minimized to a level that is As Low As Reasonably Practicable (ALARP).

ALARP principle is basically represented by the above risk triangle with high risk ( indicated by red color) on the top and low risk (green color) at the bottom. And medium risk is located somewhere in the middle. When a risk is reduced by mitigations or measures, the degree of risk is decreased from high to low. Risks above the Upper Tolerability Limit is intolerable which risk reduction is a must. Between the Upper and the Lower Tolerability Limit, the risk is only tolerable if it is ALARP, which means that all reasonably practicable risk reduction measures have to be identified and implemented. Lastly, below the Lower Tolerability Limit, risk is broadly tolerable or accpetable. ALARP is a point at which a risk is reduced so low that further risk reduction measure is not required. ALARP is simply a balancing of risk reduction and the cost of achieving it.

3. What is IDLH?

Immediately Dangerous to Life and Health limits (IDLHs) are workplace exposure limits that are meant to protect workers when they are exposed to a toxic chemical in the course of their work.

The National Institute of Occupational Safety and Health (NIOSH) defines an immediately dangerous to life or health condition as a situation "that poses a threat of exposure to airborne contaminants when that exposure is likely to cause death or immediate or delayed permanent adverse health effects or prevent escape from such an environment." Examples of gases which may pose an IDLH atmosphere include oxygen-displacing gases, such as argon, nitrogen, carbon dioxide, helium, or even steam.

For example: The IDLH level for carbon monoxide is

1200 ppm.

IDLH values are established

(1) To ensure that the worker can escape from a given contaminated environment in the event of failure of the respiratory protection equipment and

(2) To indicate a maximum level above which only a highly reliable breathing apparatus, providing maximum worker protection, is permitted.

Some types of atmospheres contain concentrations of hazardous substances that place the worker in immediate danger because these concentrations would impair the ability to leave the work area (self rescue) or potentially cause irreversible health effects, including serious injury or death in a matter of minutes.

There are particular conditions that are considered

"Immediately Dangerous to Life or Health (IDLH)". These include :

•

A known contaminant at a concentration known to be IDLH

•

A known contaminant at an unknown concentration with the potential to be IDLH

•

An unknown contaminant at an unknown concentration

•

An untested confined space

•

An oxygen-deficient atmosphere

•

Firefighting

•

Contaminants at or above 20% of their lower explosive limit (LEL—the concentration at which the gas or vapour could ignite).

4. Explain Lockout/Tagout (LOTO).

Lockout/Tagout (LOTO) refers to the specific practices and procedures for safely de-energizing and re-energizing equipment when service or maintenance must be performed.

Terms

Lockout : The placement of a lock on an energy-isolating device. This act prevents workers from energizing and operating a piece of equipment until the lock is removed.

Tagout : The placement of a tag on an energy-isolating device. A tagout device is a prominent warning device of a lockout.

Hazardous Energy Sources: This term applies to stored or residual energy such as that in capacitors, springs, elevated machine members, rotating flywheels, hydraulic systems, and air, gas, steam, or water pressure.

Procedure

Proper lockout/tagout (LOTO) procedures save workers from severe injuries and death. If equipment starts up during maintenance, workers can be caught in the machinery and suffer electrocutions, fractures, lacerations, crushing injuries, amputations, or fatalities.

- Energy can be dangerous, and machines may be powered by multiple sources. To fully de-energize a machine it must be completely disconnected from its source of power (electricity, steam, gas, pneumatics or hydraulics, etc.) and go through a total equipment shutdown, ensuring that there is no risk for the system to release any remaining stored energy.

- Watch out for stored energy. Machines can store energy in raised loads, coiled springs, charged capacitors, etc., even after the energy sources have been turned off. Make sure stored energy is depleted before starting maintenance.

Basic elements of a lockout safety program

1.

Identify which energy sources need to be locked out

2.

Can device be locked out?

- If an energy-isolating device have the capability to be locked, it should be.

- If not, then a tagout system that meets additional training and inspection requirements will be sufficient.

3.

Establish lockout/tagout procedure

4.

Assign locking/tagging duties to specific individual

5.

Employ maintenance team

6.

Ensure all stored energy has been released

Disconnect machine from all power sources (remember, some machines use multiple kinds of energy) and walk through total equipment shutdown, making sure there isn’t any energy left in capacitor banks, coils, etc.

7.

Proceed with maintenance/service as determined by company protocol

8.

Before returning machinery to operation and removing locks/tags, make sure that:

- Equipment is in the “off” position

- The equipment has been properly re-assembled

- Equipment is reconnected to power sources

9.

Follow company protocol for unlocking and/or untagging and returning machines to service

Remember: only the person who applied locks/tags should remove them!

5. What is Air Dispersion Modelling?

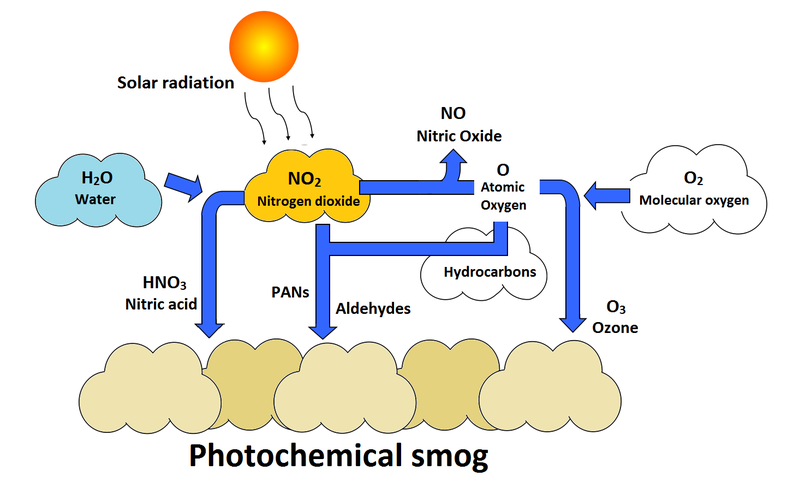

Air dispersion modeling is the mathematical simulation of how air pollutants disperse in the ambient atmosphere. It is performed with computer programs that include algorithms to solve the mathematical equations that govern the pollutant dispersion. The dispersion models are used to estimate the downwind ambient concentration of air pollutants or toxins emitted from sources such as industrial plants, vehicular traffic or

accidental chemical releases. They can also be used to predict future concentrations under specific scenarios (i.e. changes in emission sources). Therefore, they are the dominant type of model used in air quality policy making. They are most useful for pollutants that are dispersed over large distances and that may react in the atmosphere.

Dispersion models are tasked with protecting and managing the ambient air quality. The models also serve to assist in the design of effective control strategies to reduce emissions of harmful air pollutants.

Air dispersion models are also used by public safety responders and emergency management personnel for emergency planning of accidental chemical releases. Models are used to determine the consequences of accidental releases of hazardous or toxic materials, Accidental releases may result in fires, spills or explosions that involve hazardous materials, such as chemicals or radionuclides. The results of dispersion modeling can provide an estimate of location impacted areas, ambient concentrations, and be used to determine protective actions appropriate in the event a release occurs. Appropriate protective actions may include evacuation or shelter in place for persons in the downwind direction.

The dispersion models vary depending on the mathematics used to develop the model and the required data include:

- Meteorological conditions such as wind speed and direction, the amount of atmospheric turbulence (as characterized by what is called the "stability class"), the ambient air temperature, the height to the bottom of any inversion aloft that may be present, cloud cover and solar radiation.

- Source term (the concentration or quantity of toxins in emission or accidental release source terms) and temperature of the material

- Emissions or release parameters such as source location and height, type of source (i.e., fire, pool or vent stack) and exit velocity, exit temperature and mass flow rate or release rate.

- Terrain elevations at the source location and at the receptor location(s), such as nearby homes, schools, businesses and hospitals.

- The location, height and width of any obstructions (such as buildings or other structures) in the path of the emitted gaseous plume, surface roughness or the use of a more generic parameter "rural" or "city" terrain.

The atmospheric dispersion models are also known as atmospheric diffusion models, air dispersion models, air quality models, and air pollution dispersion models.

Benefits of Air Dispersion Modelling

- Air emissions from stacks and other sources can cause health and nuisance problems not only in the locality but sometimes 10’s of km away.

- Air Dispersion Modelling can predict whether there will be problems with emissions from a site and help explore the effect of various solutions.

- The Air Dispersion model will take the stack emissions and combine these with the weather conditions and effects of topography (hills, buildings etc.) and then predict the concentration at ground level of the emissions. The concentration of the substances are then generally compared to the Ambient Air Quality standards.

6. What is Industrial Ventilation?

Definition:

Ventilation is the

mechanical system in a building that brings in "fresh" outdoor air

and removes the "contaminated" indoor air.

In a workplace,

ventilation is used to control exposure to airborne contaminants. It is

commonly used to remove contaminants such as fumes, dusts, and vapours, in

order to provide a healthy and safe working environment.

Ventilation is

considered an "engineering control" to remove or control contaminants

released in indoor work environments. It is one of the preferred ways to

control employee exposure to air contaminants.

Ventilation can be

accomplished by natural means (e.g., opening a window) or mechanical means

(e.g., fans or blowers).

Purpose of a

ventilation system:

· Provide a continuous supply of fresh outside air.

· Maintain temperature and humidity at comfortable levels.

· Reduce potential fire or explosion hazards.

· Remove or dilute airborne contaminants.

Other ways to control

contaminants include:

· Eliminate the use of the hazardous chemical or material,

· Substitute with less toxic chemicals,

· Process change, or

· Work practice change.

Basic types of

ventilation systems:

There are two types of

mechanical ventilation systems used in industrial settings:

General

Exhaust (Dilution) Ventilation Systems

General exhaust ventilation,

also called dilution ventilation, is different from local exhaust ventilation

because instead of capturing emissions at their source and removing them from

the air, general exhaust ventilation allows the contaminant to be emitted into

the workplace air and then dilutes the concentration of the contaminant to an

acceptable level (e.g., to the PEL or below). Dilution systems are often used

to control evaporated liquids.

Local exhaust ventilation captures

contaminates at or very near the source and exhausts them outside.

Components of

local exhaust ventilation:

A local exhaust system has six basic elements

· A "hood" or opening that captures the contaminant at the

source.

· Ducts that transport the airborne chemicals through the system.

· An air cleaning device that removes the contaminant from the moving air

in the system (not always required).

· Fans that move the air through the system and discharge the exhaust air

outdoors.

· An exhaust stack through which the contaminated air is discharged.

· Make up air that replaces the exhausted air.

·

Basic components of a local exhaust system

HVAC

HVAC (heating, ventilating, and air-conditioning) is a common term

that can also include cooling, humidifying or dehumidifying, or otherwise

conditioning air for comfort and health. HVAC also is used for odor control and

the maintenance of acceptable concentrations of carbon dioxide.

7. Safety

in material handling at construction site

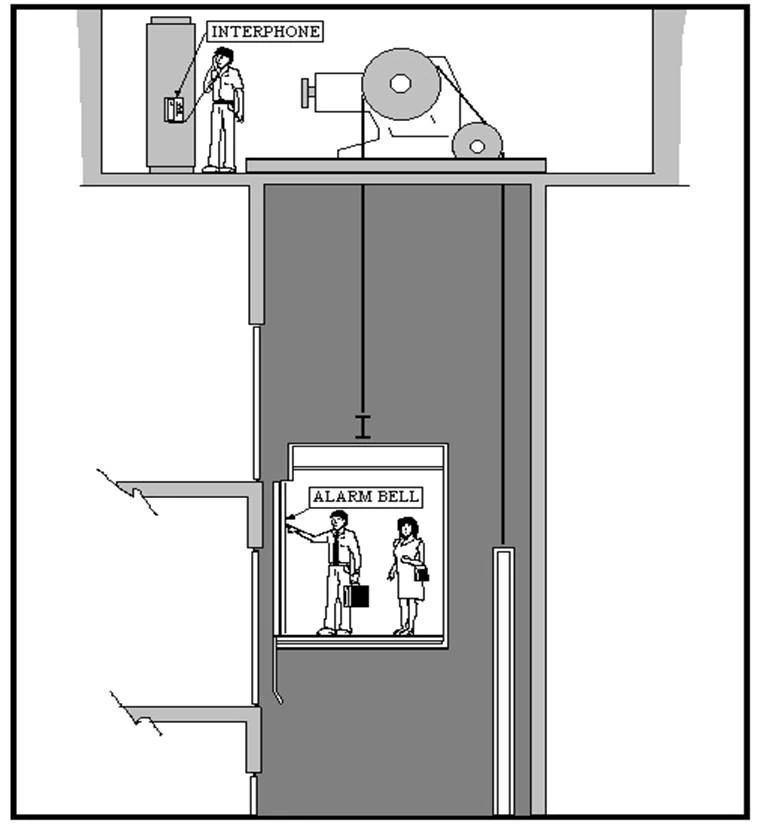

During construction,

large numbers of material handling equipment like cranes, chain pulley blocks,

hoists, lifts and other lifting accessories are used for transferring/lifting

of different construction materials, heavy structures etc.

Various types of

hazards such as crush injury due to fall of material, caught in-between moving

part of crane, collapse of crane, overturning of crane are associated with this

material handling equipment that may cause loss of life and property.

To prevent the hazards

associated with the material handling, the following important measures need to

be taken

- No lifting machine, chain, rope or

lifting tackle should be taken into use for the first time unless it has been

tested and examined by a competent person and a certificate of such a test and

examination specifying the safe working load and signed by the person making

the test and the examination is kept available for inspection.

- Cranes should be operated only by authorized

persons who are well trained and experienced.

- Regular inspection and maintenance of

material handling equipment should be scheduled and carried out. Load testing

of crane at specified load should be carried out by Competent Person at least

once in twelve months.

- Standard signals given by an authorized

signalman should be used so that the operator and user are able to synchronize

their communication.

- Care should be taken to prevent

accidental approach to live electric overhead line.

- The load to be lifted should not exceed

the Safe Working Load (SWL).

- The load to be lifted should be secured

tightly to prevent falling during lifting.

- Material handling operations should be

carried out under supervision. Lift area should be cordoned off during the

lifting operation. No one should be under/close to any working crane or

suspended load.